- +49 (0) 89 780297 0

- Partners

- Resources

- Contact

- +49 (0) 89 780297 0

- Selectors

- Machine Vision

- Machine Vision

- Cameras

- Frame Grabbers

- Frame Grabbers

- All Frame Grabbers

- All Frame Grabbers

- KY-CXP-12G-1CH-PCIe2x4

- KY-CXP-12G-2CH-PCIe3x8/x16

- KY-CXP-12G-4CH-PCIe3x8/x16

- KY-CXP-12G-4CH-PCI104

- KY-CLHS-10G-4CH-PCIe3x16

- KY-CLHS-10G-4CH-PCIe3x8

- KY-CoF-10G-4CH-PCIe3x8

- KY-CXP-12G-8CH-PCIe3x16

- KY-CXP-12G-4CH-PCIe3x8-MXM

- KY-CXP-12G-1CH-PCIe2x2-M.2

- KY-COF-12G-1CH-PCIe2x4

- KY-CLHS-12G-1CH-PCIe2x4

- KY-Thunderbolt

- KY-CLHS-10G-2CH-PCIe3x16

- KY-CLHS-10G-2CH-PCIe3x8

- KY-CoF-10G-2CH-PCIe3x16

- GD-CXP-12G-8CH-PCIe3x8

- GD-CL-850M-2CH-PCIe3x8

- GD-10GigE-20G-2CH-PCIe3x8

- GD-CXP-12G-4CH-PCIe3x8

- GD-10GigE-20G-2CH-PCIe3x4-Jetson

- GD-10GigE-40G-4CH-PCIe3x4-Jetson

- GD-CL-20G-2CH-PCIe3x4-Jetson

- GD-CXP-40G-4CH-PCIe3x4-Jetson

- ED-CL-220M-1CH-PMC

- ED-CL-220M-2CH-PCI

- ED-CL-220M-2CH-cPCI

- ED-CL-400M-2CH-PCIe2x1

- ED-CL-850M-2CH-PCIe2x4

- ED-Fiber-220M-2CH-PCI

- Frame Grabber Selector

- CoaXPress

- CXP over Fiber

- CameraLink

- CLHS, 10GigE, and Fiber

- PC104 and MXMPCIe, PCI-104, MXM, M.2, Thunderbolt 3.0

- Kaya Instruments

- Kaya Instruments

- KY-CXP-12G-1CH-PCIe2x4

- KY-CXP-12G-2CH-PCIe3x8/x16

- KY-CXP-12G-4CH-PCIe3x8/x16

- KY-CXP-12G-4CH-PCI104

- KY-CoF-10G-4CH-PCIe3x8

- KY-CLHS-10G-4CH-PCIe3x16

- KY-CLHS-10G-4CH-PCIe3x8

- KY-CXP-12G-8CH-PCIe3x16

- KY-CXP-12G-4CH-PCIe3x8-MXM

- KY-COF-12G-1CH-PCIe2x4

- KY-CLHS-12G-1CH-PCIe2x4

- KY-CXP-12G-1CH-PCIe2x2-M.2

- KY-Thunderbolt

- KY-CLHS-10G-2CH-PCIe3x8

- KY-CLHS-10G-2CH-PCIe3x16

- KY-CoF-10G-2CH-PCIe3x16

- Gidel

- EDT

- Camera Simulators

- Extenders

- IP Cores

- FMC Boards

- Multi. Camera Recording

- Custom Development

- FPGA Boards

- FPGA Boards

- FPGA Board Selector

- All FPGA Boards

- BittWare FPGA Boards

- BittWare FPGA Boards

- 520N-MX, Stratix 10 MX, 4x QSFP, 32 GB

- IA-840F, Intel Agilex AGF027

- IA-420F, Intel Agilex AGF014

- IA-220-U2, Computational Storage Processor

- 250-SoC, NVMe-over-Fabric

- 250-U2, Proxy Inline Acceleration

- XUPP3R, Xilinx Ultrascale+, 4x QSFP, 512 GB

- XUPVV8, Xilinx UltraScale+, 4x QSFP-DD, 128 GB

- S7t-VG6 Achronix Speedster7t

- IA-860m, Intel Agilex 7 AGM039

- IA-780i, Intel Agilex 7 AGI019/023

- IA-440i, Intel Agilex 7 AGI019/023

- AV-860h, AMD Xilinx Versal XCVH1582

- AV-870p, AMD Xilinx Versal XCVP1502/1552

- IA-720i, Intel Agilex 7 AGI023

- Gidel FPGA Boards

- EDT FPGA Boards

- EDT FPGA Boards

- ECL / LVDS-E / RS-422-E Mezz

- PCIe4 CDa LVDS or RS-422 configurable DMA interface

- PCIe8g3 S5-40G – Intel Stratix V FPGA, 1x 40G QSFP+, 2x 10G SFP/+s

- PCIe8g3 S5-10G – Intel Stratix V FPGA, 4x 10G SFP/+s

- PCIe8g3 A5-10G – Intel Arria V FPGA, 2x 10G SFP/+

- Bridge, Backpanel, and Time Boards

- PCIe8 CML-ECL

- PCI CDa

- Intel Agilex

- Intel Agilex

- BittWare IA-220-U2, Computational Storage Processor

- BittWare IA-420F, Intel Agilex AGF014

- BittWare IA-840F, Intel Agilex AGF027

- BittWare IA-860m, Intel Agilex 7 AGM039

- Bittware IA-780i, Intel Agilex 7 AGI019/023

- Bittware IA-440i, Intel Agilex 7 AGI019/023

- Bittware IA-720i, Intel Agilex 7 AGI023

- Intel Stratix 10

- Intel Arria 10

- Xilinx UltraScale+

- AMD Xilinx Versal

- Achronix

- Stratix IV and V, Arria V

- Stratix IV and V, Arria V

- EDT ECL / LVDS-E / RS-422-E Mezz

- EDT PCIe4 CDa LVDS or RS-422 configurable DMA interface

- EDT PCIe8g3 S5-40G – Intel Stratix V FPGA, 1x 40G QSFP+, 2x 10G SFP/+s

- EDT PCIe8g3 S5-10G – Intel Stratix V FPGA, 4x 10G SFP/+s

- EDT PCIe8g3 A5-10G – Intel Arria V FPGA, 2x 10G SFP/+

- EDT Bridge, Backpanel, and Time Boards

- Arria 10 Daughterboard

- Gidel IP and Dev Kits

- Gidel Custom Development

- Servers and Data Acquisition

- Servers and Data Acquisition

- Server Selector

- BittWare TeraBox 5202S, 10x FPGA, 40x QSFP

- Bittware TeraBox 1501B/1502B, 4x FPGA

- Bittware TeraBox 1400B, 5 FPGS, 16 QSFP

- Bittware TeraBox 1102S, 4x FPGA

- Bittware TeraBox 2202D, 6x FPGA, 6x QSFP-DDs

- Bittware TeraBox 210DE, 4x FPGA, 6x QSFP-DDs

- EDT SNAP1 – 1U data acquisition, storage, and playback

- EDT μWRAP 25 GB compact record and playback

- EDT NVMe RAID carrier board 8 TB

- EDT uWRAP VITA 49

- EDT WBX Recorder

- EDT TacWRAP VITA 49

- EDT Edgeblade SSA, 64 TB, 40 G

- EDT Edgepoint.AI with NVIDIA

- EDT Microblade Recorder

- Plasma

- Plasma

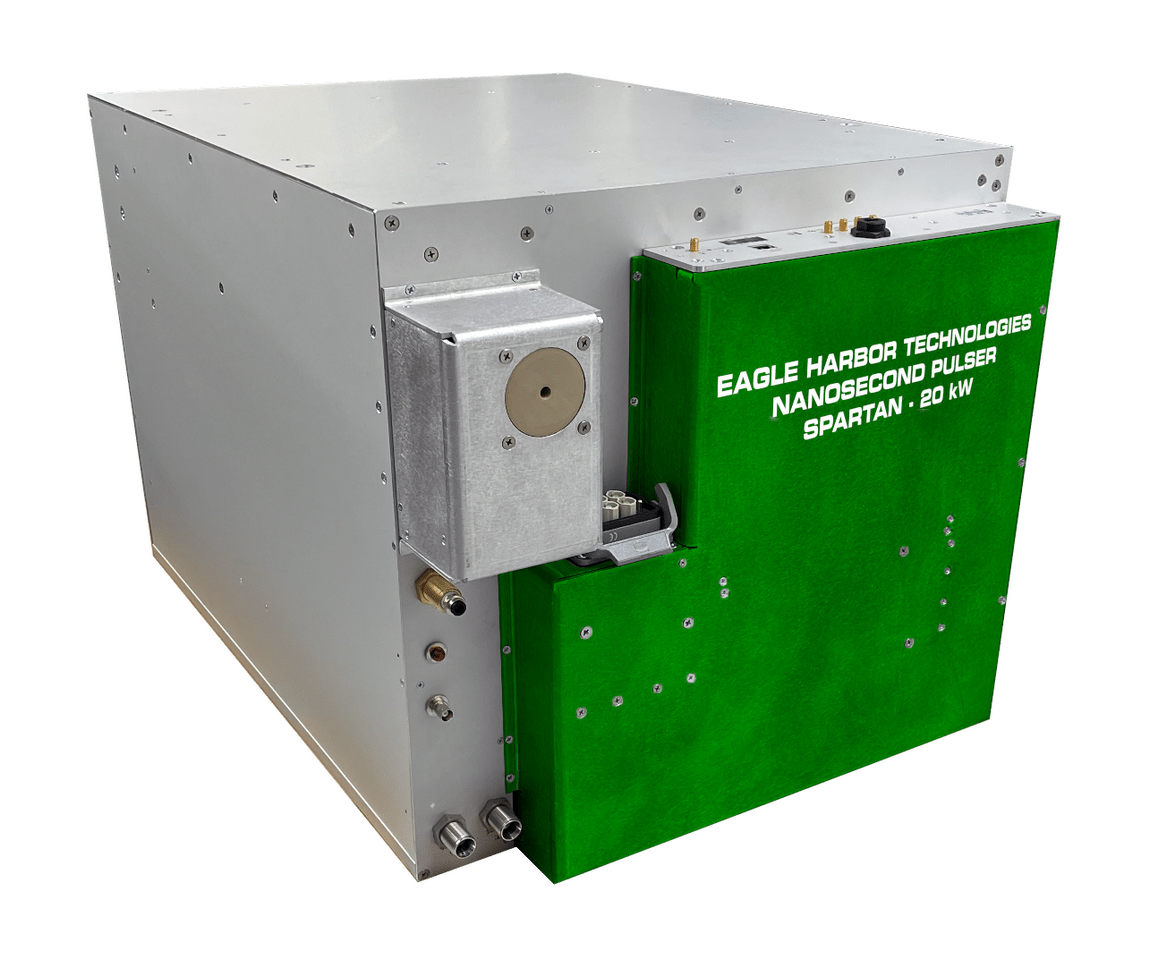

- Nanosecond Pulsers

- Electroporation

- High-Voltage Bipolar Microsecond Pulser

- High-Power Solid-State Switches

- High-Voltage Pulse Generators

- Switching Power Amplifiers

- Pulse Amplifier/Puff Valve Driver

- Fiber-optic Isolators

- Differential Integrators for Magnetic Diagnostics

- High Power Custom Power Supplies

- Charge / Dump Control

- Rapid Capacitor Charger

- Application Specific Power Supplies

- Inductive Adder

- 40 kA PWM Coil Driver

- EHT Semiconductor Fabrication

- Legacy

- Legacy

- Engineering Design Team

- Engineering Design Team

- EDT PCIe8 LX – high-speed DMA

- EDT PCI GS – DMA Accelerator

- EDT AMC FX5 – uTCA Main Board

- EDT 3P Mezz – 10 Gb, 1 GbE, or up to OC48 (STM16) interface

- EDT OC192 Mezz – Optical multi-rate to OC192 / STM64 / 10 GbE

- EDT OCMP Mezz – Optical or electrical 1 GbE

- EDT OCM 2.7G Mezz – Optical AMC 2.7 Gb/s

- EDT 3x3G Mezz – 3 Gbs or 1 GbE RocketIO

- EDT HRC Mezz – PCI/e, E4, STS3, OC3/STM1

- EDT MSDV Mezz – 4x DVB-ASI/SMPTE

- EDT 16TE3 Mezz

- EDT Combo Mezz - E1/T1, E3/T3, ECL Interface Card

- EDT Combo2 Mezz - E1/T1, E3/T3, LVDS or RS-422 interface

- EDT Combo3 Mezz – E3/T3, ECL, or LVDS/RS-422 interface

- EDT SRXL Mezzanine board. Signal receiver and processor for IF and L-band

- EDT SRXL2 Mezz – Programmable L-band and IF

- EDT DDRX16 Mezz – DSP dual digitizer, 16-bit A/D converters

- EDT SSE Mezz – DSP Synchronous serial ECL interface

- EDT XIOS – 2U Server, 10x PCI or PCIe

- EDT EXP4 – 1U expansion system for PCIe2 x8

- EDT WSU1 – 1U 9.8 TB Data Acquisition Mass Storage Unit

- EDT WRAP 10G Server – Wideband recording and playback

- EDT PCIe8 DVa CLS Camera Link

- EDT PCIe8 G3 A5-40G full- or half-height – Itnel Arria V FPGA, 40G QSFP+

- EDT PCIe8g3 KU-40G – Ultrascale, 1x 40G QSFP+, 2x 10G SFP/+s

- EDT PCIe8 G3 KU-10G – Ultrascale, 4x 10G SFP/+s

- Kaya Instruments

- Gidel

- Eagle Harbor Technologies

- Network Appliances

- MultiCamera Systems

- Syscom